“Implementing requirements optimally and striving for continuous perfection”

Barely any other industry requires control quality at this level. The challenges for the control process are further increased by several boundary conditions: New technical plastics with high temperature-sensitivity, new smaller injection moulds and high levels of parallelism pose extreme challenges for tool makers, hot-runner system manufacturers and control manufacturers.

The injected quantities of plastic and the associated very small nozzles and ever faster heaters are the new measuring stick for highly effective control. Today's high-quality controllers need to regulate heating from 20°C to 250°C in a few seconds with minimal overshoot. The new ELOTECH hot runner controls were developed for these extreme requirements. While some control systems regulate slowly in order to avoid major overshoot, other systems work according to the principle of fast regulation with a high level of overshoot. In the first case, valuable production time is lost. In the second there is an increased danger of damage to the nozzle with considerable secondary impact in the event of a leak. The new ELOTECH RT family combines the positive characteristics.

Made in Germany

stands for German engineering and production technology. The RT family offers optimum control characteristics and easy operation with optimum price-performance ratio. The expertise from more than 250,000 industrial temperature control applications have fed into the ELOTECH control algorithm. Continuous software development has enabled ELOTECH to develop this unique algorithm. ELOTECH has also been supplying electronic modules, including control software, to two hot-runner control manufacturers for many years and has built up further expertise in the process.

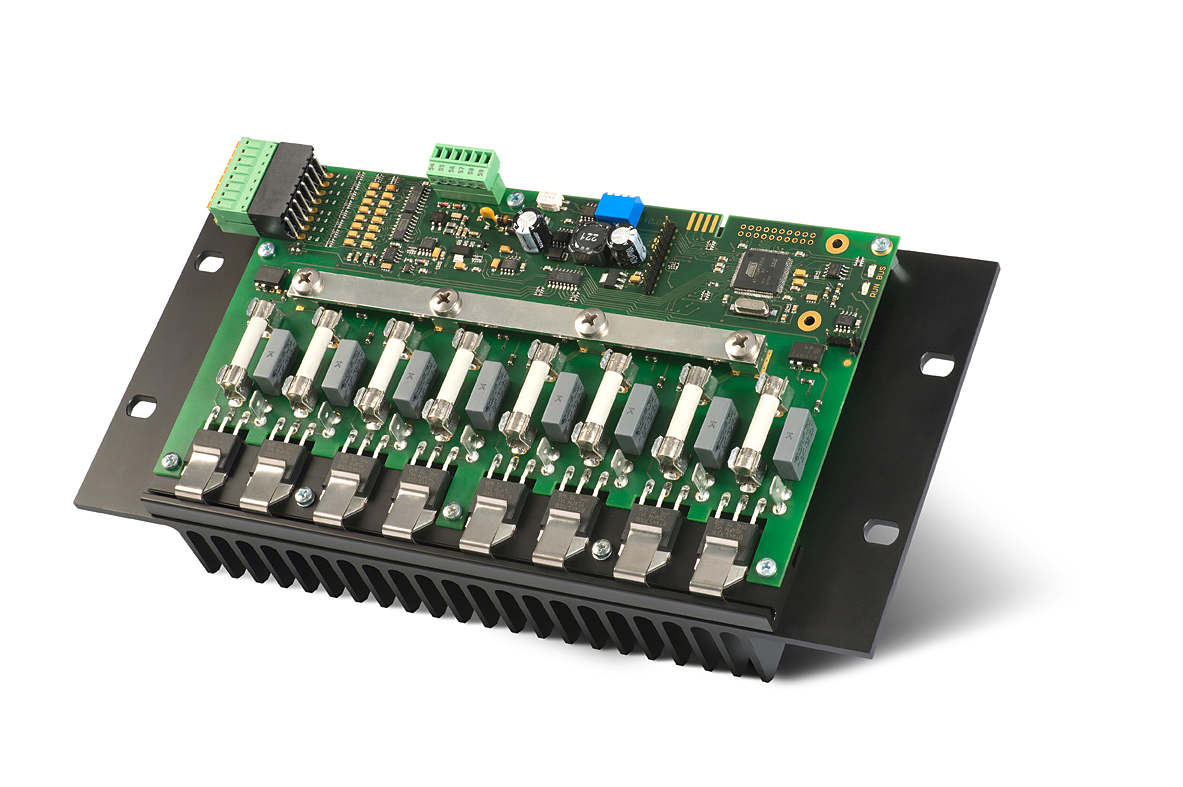

The RT1000 and RT4000 product lines are based on standard controllers, which are used in high quantities in many industrial applications. The RT7000 control was developed with the latest technological approaches. In 2021 we will be adding further variants with external fuses to this family.

Depending on the equipment variant of the RT7000, it incorporates several CCM1000 modules. Each CCM1000 switches 8 heaters via Triacs (230 VAC). The integrated fuses protect the individual zones with maximum 16 Ampere; a total current of the whole module of maximum 48 Ampere. Depending on the equipment variant of the RT7000, the total currents are adapted correspondingly.

The performance features of the RT family:

- Very rapid adjustment without major overshoot

- Simple, intuitive operation

- New operating concepts with Webserver and APP

- Excellent price/performance ratio

The benefits to you:

- Shorter machine warm-up time and longer production times – optimised system exploitation

- With minimum overshoot – considerable reduction of damage to the nozzle and thus less failure times and higher productivity

- Fewer operating errors and less use for expensive training

- Easy integration, better remote maintenance and faster support

The algorithm is the decisive measure in all things

25 years of experience and 250,000 applications in the industrial environment ensure that this algorithm achieves outstanding control results. Constantly striving for continuous improvement means that we now achieve very fast control with minimum overshoot.

The secret: The individual parameters automatically adapt in millisecond cycles to the situation and ensure corresponding control results. The interplay of the individual parameters is also an essential feature in order to optimally control even very high-speed controlled systems, as is the case with very small nozzles or heating rods, for example. Example: From 20°C to 250°C in under 3 seconds with an overshoot of just a few Kelvin. The controlled status is reached in 10 seconds.