RT7000 - Innovative hot runner control from ELOTECH

20 years of experience in hot runner control

Your hot runner control as OEM product

- Your own housing design and your own user interface = your individual product

- Unified operation within the device family

- No comparison with other competitor's products

Performance features

- Compact hot runner control

- High control precision - improvement of the casting process and reduction of waste

- Low energy consumption thanks to compound heating

- Optimised PID control algorithm specially for hot runner systems

- Ramp function

- Soft start

- Heater current monitoring

- Self-optimising

- Boost function

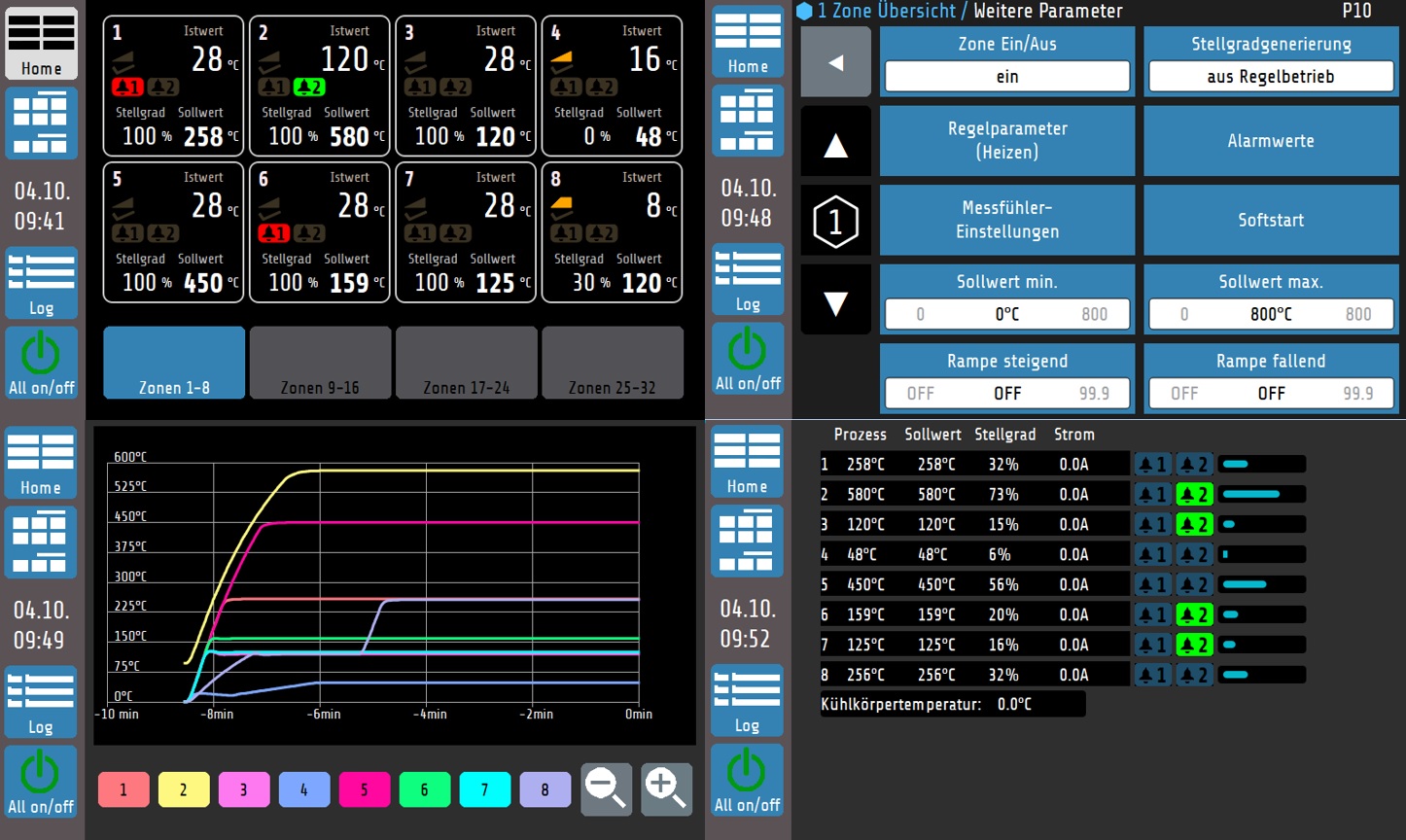

- Graphical display of the individual zones as well as the PID values, output ratio and setpoints/actual values

- Log book display and data backup

- Interfaces: Ethernet, USB, Modbus, Profibus DP, Canopen, Profinet and OPCUA (in development)

- Various protocols including Arburg, …

Operation

- 7-inch touch display

- Remote control via viewer software. Screen share via Ethernet to company network ("Viewer"). Access via PC, Smartphone, Tablet etc.

- Intuitive operation thanks to clear layout

- Option: Operation via keyboard and mouse

- Option: Connection of a further monitor

Basic operating functions

- Click on the setpoint to open another window in which you can change the setpoint.

- On/off switching of individual zones

- Choose between automatic and manual modes. In manual mode, the manual output level is activated. Soft-start function is switched off.

- Simple copying of parameters to other zones by individually selecting the zones.

- Change zone numbers via offsets or using individual digit (order of priority: 1. Offset, 2. Individual number, 3. System numbering)

- Logbook function

Commissioning functions

- Sensor type adjustment: Select from a wide range of sensor types. Select between linear inputs, PT100 or different thermocouples.

- Individual blocking of different areas. User management with password protection

- Efficient hot runner system monitoring before commissioning the tool. (correct cabling and thus avoidance of premature damage to sensors or heating elements).

- Replacement of fuse: You can change a fuse without additional tools, simply by releasing the cover. (depending on housing variant). The fuses for heaters and thermocouples are located directly on the power board and can be rapidly replaced.

Safety functions

- Individually adjustable monitoring: Messages in the case of temperature alarm in the case of one or more zones, sensor errors, heat sink temperature, switch-on disable, system error, current alarms, energy surges per zone and of the system, …

- Leakage alarm: Rapid, unplanned temperature or energy increase, e.g., at a nozzle, can be an indicator of a leak. Automatic energy monitoring means expensive downtimes are avoided. (in development)

- Stop heating in the event of error message or downtime

- Automatic data backup via USB memory

Monitoring

- Settings in the case of temperature alarm: Min. and max. value whether absolute or relative to setpoint? Delay value for alarm, self-locking (on/off), system standby

- Fuse failure

- Adjustable current alarm limit values for each zone including leakage current limit and display of actual leakage current.

- Intelligent output limitation

(some of these features are still in development)