Developed to your specifications

We think holistically. We design the requirement specification, develop the circuit board and software and even produce the housing in consultation with you. To reduce development costs, ELOTECH endeavours to use existing hardware and software platforms. This simultaneously guarantees the availability of components and cost-effective procurement thanks to material-bundling.

To accelerate the development process, we produce most functional samples and prototypes ourselves. The same also applies for the construction of the assembly test systems. We deliver the series product to you, including instructions and training, at the time and date agreed in the framework contract. ELOTECH will of course also carry out the subsequent servicing.

Leave it to us. When it comes to control and regulation applications, we are the right partner. We also incorporate new technologies, including Cloud and OPC-UA.

Two routes to customised development

Platform-based solutions

ELOTECH currently offers three different hardware-platforms for customer-specific product solutions. As well as a PIC-based variant (RS1500) and a Cortex-processor platform (RS41X0), we supply high-performance iMX6-hardware for complex regulation and control tasks. Based on these products ELOTECH develops individual regulation and control systems for you according to your performance specifications.

Your Benefits:

- Rapid and cost-effective development because most of the hard and software is instantly available

- Major experience potential in the area of industrial interfaces and applications

The individual solution

For particular requirements ELOTECH gives you complete individually developed solutions. Control functionality, interfaces and functions are thus tailored precisely to your needs. We develop the requirement specification together with you and present you with the best solutions. These may be purely control products for very particular requirements, combined regulation and control solutions or individual machine controls.

As well as software and hardware development we also make the overall solution the focal point of our considerations. This includes test systems, traceability and the right production and service concepts. We provide you with precise delivery timetables for your products. We also have an comprehensive cancellation and after-sales service.

Applications:

- Controllers for temperature, pressure, flow and other process values

- Machine controllers

- Indicators

- Monitoring devices

Examples of platform solutions

Custom controllers

Do you have a lot of power to regulate? Do you want to integrate your regulator with a power controller in a 19-inch rack or perhaps in a control cabinet on castors? Perhaps you don't have your own control cabinet construction department or you lack the expertise in-house to implement such a solution? If you answered yes to any of these questions, you are in the right place. We supply you with your individual housing solution.

In large industrial plants where high-powered heating is used, contactors are used as power controllers. In this case for example, 6 zones are wired respectively via separate contactors (total: 90 A at 230V / Phase). The complete system is designed for 80KW. The A4000 indicator operates as an additional monitoring system with separate sensors. At the customer's request, we integrated additional protection systems, such as individual fusing of each line or the emergency stop switch. This "power controller" is used in a tool-making press.

If you need to switch more power than the ELOTECH RT family allows (max. 32A at 400V), we can supply complete control cabinet solutions, all made in-house, including implementation of the electrical design and preparation of the control cabinet documentation.

Get in touch. We can find a solution for your problem.

16-zone PID controller in switch cabinet format

This solution is equipped with two 8-zone R4000s. The 16 x 25A solid state relays switch each zone up to 3.5 KW. Communication with the outside world takes place via a Profinet interface. Active cooling ensures the right climate. Each zone is also fused with B16A automatic circuit breakers and each controller also has two 50A fuses and a main switch. The planning, construction and testing of the switch cabinet takes place taking into consideration the following regulations: DGUV (BGV A3), VDE 0100 part 540, VDE 0113 (DIN EN 60204-1) and DIN EN 61439-1.

Individual annealing control

If you want to weld together large components made of steel or cast steel, you need to anneal them first to processing temperature. This reduces heat stresses resulting from the welding process and stops deterioration of the mechanical characteristics caused by unwanted changes of the component microstructure. For this purpose, heating mats are first mounted on the component near the planned welds. These are equipped with integrated hot sensors which are individually regulated to the desired setpoint temperature.

For parallel control of up to 12 temperature zones ELOTECH has developed the R1140 annealing controller. Temperature control takes place via temperature-time profiles, which can be selected individually for each annealing zone. Amongst other things, the units communicate via integrated data interfaces. The first controller in the chain issues the process start or stop command. After the final program section has completed, a contact reports completion. The system monitors temperature limits and sensor errors independently and reports malfunctions via an integrated alarm relay.

Same platform - different application: Temperature device control

Also based on the R1140, with slight changes to the hardware and some software adaptations this controller transforms into a fully-featured control system for temperature control units. The controller is fitted with a profibus and now has four different relay outputs for heating, cooling, pump control and joint alarm. In addition, some inputs are programmed with different functions and the existing LEDs perform different indicator functions. Thus, with minimal development outlay we develop a controller which is precisely designed for your needs.

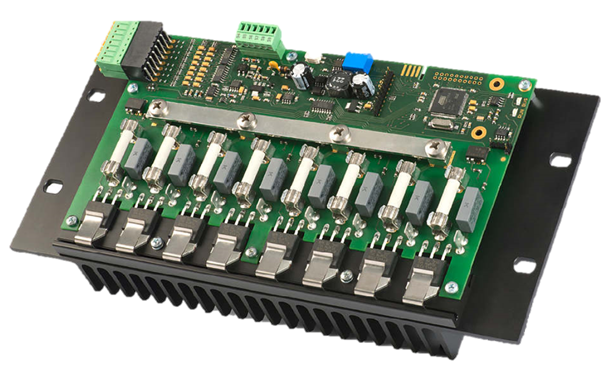

8-zone controller - separate yet unified

Eight into one, was the catchphrase for this customer-specific solution. The aim: Eight individual controllers are working in combination in a system. To increase the safety of the overall system however, the controllers are physically separated. If one controller fails, the remaining seven will carry on working independently.

Various LEDs show the status on the individual control circuit boards. Programming is carried out by the user on a manual programming appliance or using the ELOVISON software. TRIAC power controllers on the main circuit board switch the heating on/off. The main circuit board with the 8-zone controller is integrated into a robust passively-cooled metal housing. The user connects heaters and sensors directly to the housing.

Examples of individual solutions

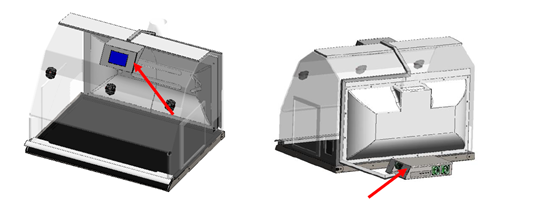

Control system for safety weighing cabin

In this project the control system, which was developed to customer preferences, carries out all system functions: Adjustment, calibration and operation of the fan, lighting and scales.

The control also records various sensors and calculates, for instance, the optimum flow through the cabin. A range of alarms is provided to ensure safe system operation.

The sensor values can be displayed graphically. All graphics are displayed on a 3.5-inch touch screen. All integrated appliances are connected to the IO assembly.

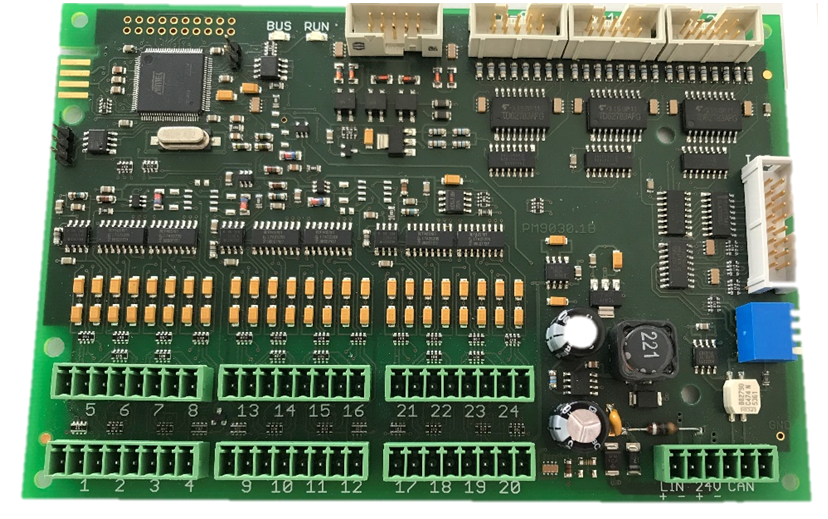

Multi-zone controller on a micro-scale

Do you need a lot of control zones? Where other control manufacturers stop, we go further. We can build control systems with several hundred control circuits individually for you. With our cascadable controller boards we can meet practically any requirement.

The aim of this assembly was to design a 24-zone controller on a very small scale. The customer's wish list also included cascading for very large control solutions. In this way we can produce controls for up to 288 zones. Each assembly has 24 thermocouple inputs. There are 24 logic outputs with 1...10 volt output signals. The system is controlled either via CAN or RS485 interface.

Robust miniature device for direct assembly onto heating systems

Small, robust, cost-effective and minimal assembly required, still with our renowned high quality control performance. This was the key factor in the design.

The transparent front housing panel provides a view of different coloured LEDs, which display the different operating statuses.

The programming and parametrising of the controller is carried out via a customer-specific remote-control unit which is connected via a cable. Up to 124 1-zone units can be connected to the control system via the RS-485 interface. The control system consists of a variation of ELOVISION, the ELOTECH Windows software which was expanded to customer-specific functions.

Compact PID controller with load outputs

This load controller fulfils all characteristics of a compact and equally high-performance product. Up to 8 zones can be connected simultaneously, divided over a 3-phase system, which allows switching of up to 48 A maximum current.

Functions such as self-optimising, soft start, heater current monitoring or alarms for under/over temperature, heating circuit failure or broken sensors are all integrated. Integrated protection against thermal overload is also installed.

Type J or K thermocouples can also be connected. Profibus, RS232 or RS485 are available as field bus interfaces.

Temperature device control

This assembly with corresponding software was developed for a customer-specific temperature device control system. Operation is via an external touch display. As well as traditional control, the electronics can also analyse further sensors and control pumps and valves.

- 3-point controller

- Fieldbus: Profibus, CAN

- USB for data storage, LAN interface

- Pump control, fluid level alarm, pressure display and control

- Alarms

- 6 inputs, 8 outputs

- Various protocols: Arburg, Engel, …

- Hybrid outputs: max. 9KW, 400V