Tool temperature control

The critical size: The temperature of the tool

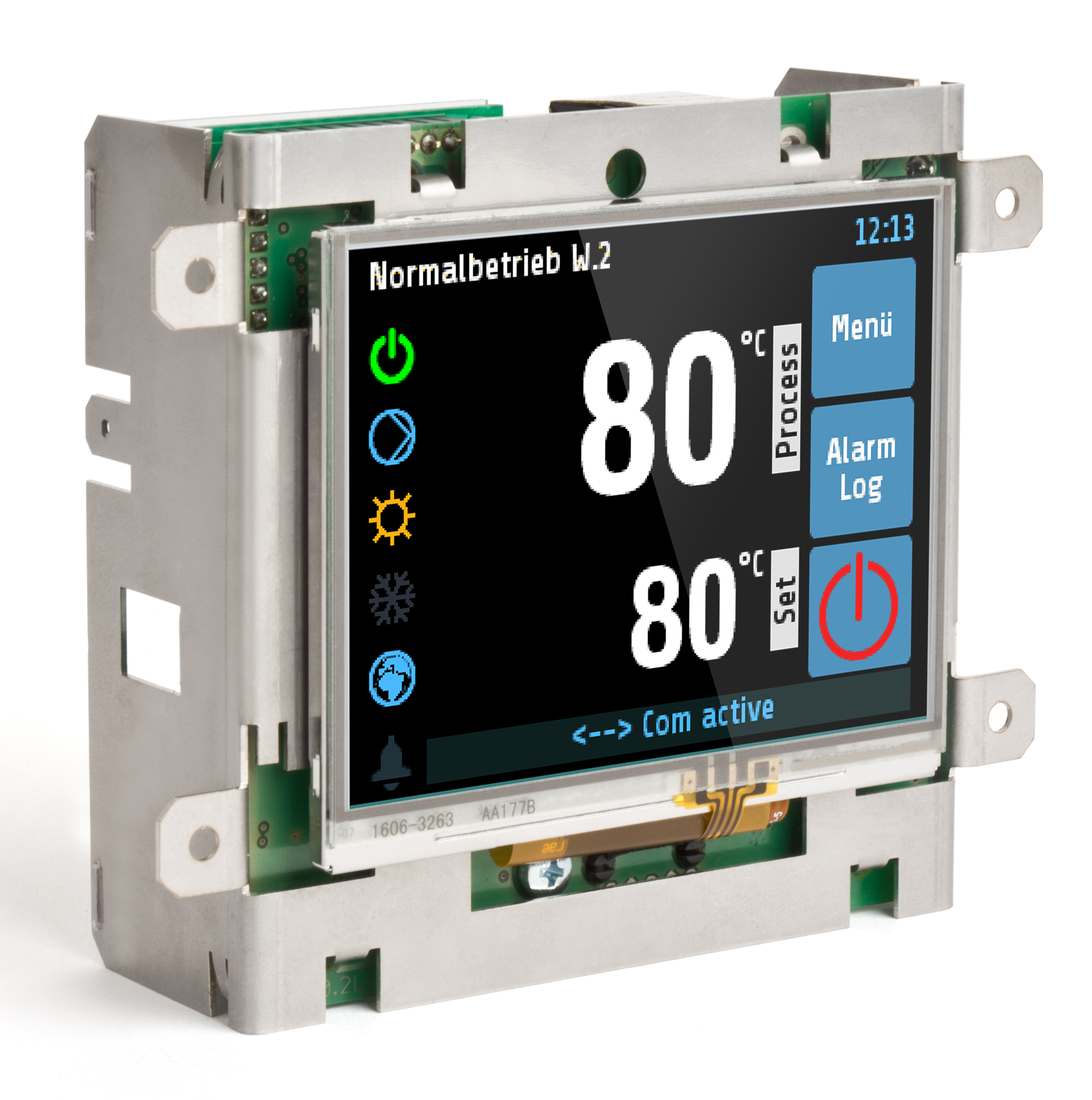

In plastics processing the control of the working temperature is of central importance. Materials such as PA or PE react to thermal overstress by carbonising, while other plastics such as POM or PUR decompose into gaseous materials, evident in the foaming of the material at the nozzle output. Discolouration, streaks or flow marks on the products are the result of faulty temperature control. Modern PID controllers like the ELOTECH R 4100 can offer effective help, even at high production speeds and short pulse times.

Applications: Continuous and intermittent processing

In this case essentially two different applications must be taken into consideration: Continuous processes such as the extrusion and cyclical processes such as injection moulding.

The prerequisite for high quality temperature control is an adapted parameterisation of the temperature controller. Determining the parameters requires details or estimates of the thermal inertia of the system. This involves the progression over time of the controlled variable after a sudden change to the manipulated variable.

PID controllers from ELOTECH measure the path values automatically and determine the parameters iteratively. The quality of the optimisation depends on the quantity of the iterations. This process is described as self-optimising.

Individual control solution needed?

We produce cost-effective individually adapted control solutions. Tell us what you need to do - we will find the solution.